| |

|

شركة التقنية العالمية لتجارة المكائن

والعدد الصناعية

|

|

International Technical Company for Industrial Machines

and Tools Trading |

|

BUG-O SYSTEMS WELDING AND CUTTING |

|

|

|

What is

BUG-O?

BUG-O Systems

Inc., a division of Weld Tooling Corporation founded in 1948, is a

manufacturer of a system of drives, carriages, rails and attachments

designed to automate welding guns, cutting torches and other hand

held tools.

more--> |

BUG-O

Increases Precision, Productivity, and

Profit! BUG-O

Increases Precision, Productivity, and

Profit!

Virtually every metal

fabrication company can save money by automating their welding and

cutting applications. Check out these facts and figures to see what

BUG-O Systems equipment can do for you.more-->

6 Ways That Automating With BUG-O Can Save You

Money:

Some fundamentals

about the benefits of automation. more-->

| |

|

|

|

|

|

|

| |

| |

|

The

BUG-GY Fillet Welder is a trackless,

self-guiding welding carriage designed for

making continuous or intermittent welds on

fillet, lap, or butt joints. It is a

lightweight, portable carriage that uses a

powerful electro magnet and guide wheels to

clamp and track on the work piece. |

|

The

BUG-GY-VERT is a portable,

battery powered, 4-wheel drive welding

carriage with torch oscillation. Strong

permanent magnets hold the machine on the

workpiece allowing it to travel on vertical

or oblique surfaces. |

|

The

UNI-BUG II will carry a cutting

torch or welding gun into tight work areas

or around very tight curves without the use

of a track. The UNI-BUG II can weld or cut

both straight lines and radii as small as 6"

(1152mm). |

|

The

UNI-BUG III will make continuous or

intermittent stitch welds. The machine will

mount and run directly on the work piece.

Each carriage is designed to fit on a

specific steel profile. |

|

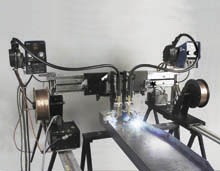

The

STIFFENER WELDER (with Lincoln feeders)

is a self contained, dual head welding

travel carriage with integrated wire feeders

and spool mounts. It will produce continuous

or programmable imtermittent fillet welds on

stiffeners with heights of 3"-16" (75-400mm)

and widths up to 12" (0-300mm). |

|

The

STIFFENER WELDER (with Miller feeders)

is a self contained, dual head welding

travel carriage with integrated wire feeders

and spool mounts. It will produce continuous

or programmable imtermittent fillet welds on

stiffeners with heights of 4" to 18"

(102-457mm) and widths of 4" to 12"

(102-305mm). |

|

The

MINI-VERT is held on the workpiece

with strong permanent magnets. It will

travel and carry a welding gun in flat or

vertical positions producing continuous

uniform fillet welds. |

|

| |

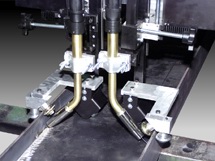

Bug-o Gantry

Bug-o Gantry and Side Beam Units are custom

designed assemblies that are used in a

variety of applications such as automated

seam welding, beam and stiffener fabrication

as well as cutting applications such as

stripping and edge preparation. |

|

Welding Flanges on

"I" Beam

|

|

|

|

|

|

| |

| |

|

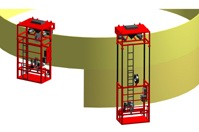

GIRTH

WELDER

The Girth Welder is a self-propelled welding

system for field storage tank welding. It

can reduce field storage tank welding time

up to 40%. Weld defects are greatly reduced

saving tank erection costs. This machine is

available as dual or single sided. The

Lincoln NA-3 control and welding head are

fitted with wire feed rolls, nozzles,

straighteners and 50 lbs (22.7 kg) wire

reels. A flux recovery system is equipped

with the machine for the recycling of flux.

An adjustable frame allows for plates 6'

(1.8m) to 10' (3m) tall. |

|

|

| |

.jpg) |

.jpg) |

.jpg) |

| |

|

|

.jpg) |

.jpg) |

.jpg) |

| |

|

|

.jpg) |

.jpg) |

.jpg) |

| |

|

|

.jpg) |

.jpg) |

.jpg) |

| |

|

|

ITC Iraq Office

International Technical Co.

Al-Rasheed Street

Morabaa, Baghdad Iraq

E-mail:

nadhimhikmet@yahoo.co.uk |

P.O.Box 15188 Yarmouk , Baghdad

Tel: (+964) 1 8858033

Mobile: (+964) 079 01332091

Fax: (+964) 1 5413932

فرع البصرة : شارع الأستقلال / موبايل 07801395542

|

|